Hankook Protec 13NF 8000 Flat Bed CNC Lathe

Swing

1300 MM

Distance Between Centres

8000 MM

Spindle Bore

440 MM

Check Availability

View machine

Hankook Protec 13NF 7000 Flat Bed CNC Lathe

Swing

1300 MM

Distance Between Centres

7000 MM

Spindle Bore

440 MM

Check Availability

View machine

Hankook Protec 13NF 6000 Flat Bed CNC Lathe

Swing

1300 MM

Distance Between Centres

6000 MM

Spindle Bore

440 MM

Check Availability

View machine

Hankook Protec 13NF 5000 Flat Bed CNC Lathe

Swing

1300 MM

Distance Between Centres

5000 MM

Spindle Bore

440 MM

Check Availability

View machine

Hankook Protec 13NF 4000 Flat Bed CNC Lathe

Swing

1300 MM

Distance Between Centres

4000 MM

Spindle Bore

440 MM

Check Availability

View machine

Hankook Protec 13NF 3000 Flat Bed CNC Lathe

Swing

1300 MM

Distance Between Centres

3000 MM

Spindle Bore

440 MM

Check Availability

View machine

Hankook Protec 13NF 2000 Flat Bed CNC Lathe

Swing

1300 MM

Distance Between Centres

2000 MM

Spindle Bore

440 MM

Check Availability

View machine

Hankook Protec 13NE 8000 Flat Bed CNC Lathe

Swing

1300 MM

Distance Between Centres

8000 MM

Spindle Bore

381 MM

Check Availability

View machine

Hankook Protec 13NE 7000 Flat Bed CNC Lathe

Swing

1300 MM

Distance Between Centres

7000 MM

Spindle Bore

381 MM

Check Availability

View machine

Hankook Protec 13NE 6000 Flat Bed CNC Lathe

Swing

1300 MM

Distance Between Centres

6000 MM

Spindle Bore

381 MM

Check Availability

View machine

Hankook Protec 13NE 5000 Flat Bed CNC Lathe

Swing

1300 MM

Distance Between Centres

5000 MM

Spindle Bore

381 MM

Check Availability

View machine

Hankook Protec 13NE 4000 Flat Bed CNC Lathe

Swing

1300 MM

Distance Between Centres

4000 MM

Spindle Bore

381 MM

Check Availability

View machine

Hankook Protec 13NE 3000 Flat Bed CNC Lathe

Swing

1300 MM

Distance Between Centres

3000 MM

Spindle Bore

381 MM

Check Availability

View machine

Hankook Protec 13NE 2000 Flat Bed CNC Lathe

Swing

1300 MM

Distance Between Centres

2000 MM

Spindle Bore

381 MM

Check Availability

View machine

Hankook Protec 13ND 8000 Flat Bed CNC Lathe

Swing

1300 MM

Distance Between Centres

8000 MM

Spindle Bore

330 MM

Check Availability

View machine

Hankook Protec 13ND 7000 Flat Bed CNC Lathe

Swing

1300 MM

Distance Between Centres

7000 MM

Spindle Bore

330 MM

Check Availability

View machine

Hankook Protec 13ND 6000 Flat Bed CNC Lathe

Swing

1300 MM

Distance Between Centres

6000 MM

Spindle Bore

330 MM

Check Availability

View machine

Hankook Protec 13ND 5000 Flat Bed CNC Lathe

Swing

1300 MM

Distance Between Centres

5000 MM

Spindle Bore

330 MM

Check Availability

View machine

Hankook Protec 13ND 4000 Flat Bed CNC Lathe

Swing

1300 MM

Distance Between Centres

4000 MM

Spindle Bore

330 MM

Check Availability

View machine

Hankook Protec 13ND 3000 Flat Bed CNC Lathe

Swing

1300 MM

Distance Between Centres

3000 MM

Spindle Bore

330 MM

Check Availability

View machine

Hankook Protec 13ND 2000 Flat Bed CNC Lathe

Swing

1300 MM

Distance Between Centres

2000 MM

Spindle Bore

330 MM

Check Availability

View machine

Hankook Protec 13NA 8000 Flat Bed CNC Lathe

Swing

1300 MM

Distance Between Centres

8000 MM

Spindle Bore

105 MM

Check Availability

View machine

Hankook Protec 13NA 7000 Flat Bed CNC Lathe

Swing

1300 MM

Distance Between Centres

7000 MM

Spindle Bore

105 MM

Check Availability

View machine

Hankook Protec 13NA 6000 Flat Bed CNC Lathe

Swing

1300 MM

Distance Between Centres

6000 MM

Spindle Bore

105 MM

Check Availability

View machine

Hankook Protec 13NA 5000 Flat Bed CNC Lathe

Swing

1300 MM

Distance Between Centres

5000 MM

Spindle Bore

105 MM

Check Availability

View machine

Hankook Protec 13NA 4000 Flat Bed CNC Lathe

Swing

1300 MM

Distance Between Centres

4000 MM

Spindle Bore

105 MM

Check Availability

View machine

Hankook Protec 13NA 3000 Flat Bed CNC Lathe

Swing

1300 MM

Distance Between Centres

3000 MM

Spindle Bore

105 MM

Check Availability

View machine

Hankook Protec 13NA 2000 Flat Bed CNC Lathe

Swing

1300 MM

Distance Between Centres

2000 MM

Spindle Bore

105 MM

Check Availability

View machine

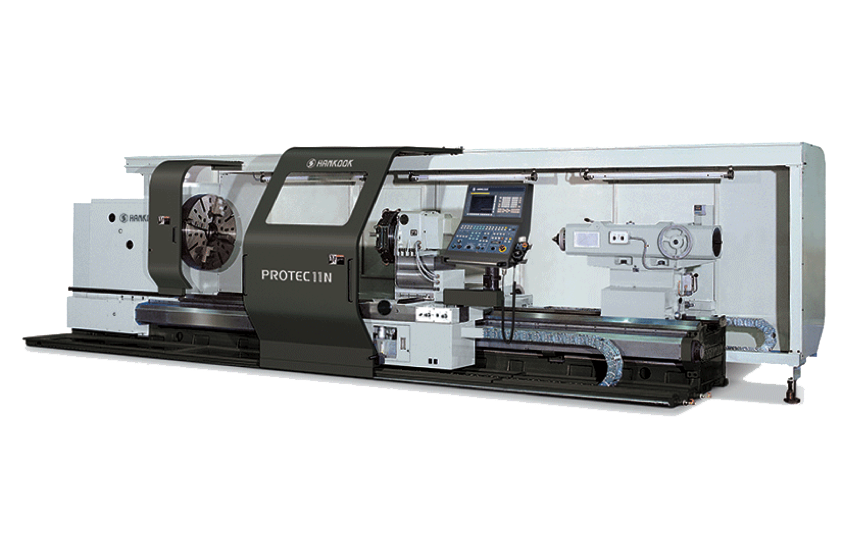

Hankook Protec 11NF 8000 Flat Bed CNC Lathe

Swing

1100 MM

Distance Between Centres

8000 MM

Spindle Bore

440 MM

Check Availability

View machine

Hankook Protec 11NF 7000 Flat Bed CNC Lathe

Swing

1100 MM

Distance Between Centres

7000 MM

Spindle Bore

440 MM

Check Availability

View machine

Hankook Protec 11NF 6000 Flat Bed CNC Lathe

Swing

1100 MM

Distance Between Centres

6000 MM

Spindle Bore

440 MM

Check Availability

View machine

Hankook Protec 11NF 5000 Flat Bed CNC Lathe

Swing

1100 MM

Distance Between Centres

5000 MM

Spindle Bore

440 MM

Check Availability

View machine

Hankook Protec 11NF 4000 Flat Bed CNC Lathe

Swing

1100 MM

Distance Between Centres

4000 MM

Spindle Bore

440 MM

Check Availability

View machine

Hankook Protec 11NF 3000 Flat Bed CNC Lathe

Swing

1100 MM

Distance Between Centres

3000 MM

Spindle Bore

440 MM

Check Availability

View machine

Hankook Protec 11NF 2000 Flat Bed CNC Lathe

Swing

1100 MM

Distance Between Centres

2000 MM

Spindle Bore

440 MM

Check Availability

View machine

Hankook Protec 11NE 8000 Flat Bed CNC Lathe

Swing

1100 MM

Distance Between Centres

8000 MM

Spindle Bore

381 MM

Check Availability

View machine

Hankook Protec 11NE 7000 Flat Bed CNC Lathe

Swing

1100 MM

Distance Between Centres

7000 MM

Spindle Bore

381 MM

Check Availability

View machine

Hankook Protec 11NE 6000 Flat Bed CNC Lathe

Swing

1100 MM

Distance Between Centres

6000 MM

Spindle Bore

381 MM

Check Availability

View machine

Hankook Protec 11NE 5000 Flat Bed CNC Lathe

Swing

1100 MM

Distance Between Centres

5000 MM

Spindle Bore

381 MM

Check Availability

View machine

Hankook Protec 11NE 4000 Flat Bed CNC Lathe

Swing

1100 MM

Distance Between Centres

4000 MM

Spindle Bore

381 MM

Check Availability

View machine

Hankook Protec 11NE 3000 Flat Bed CNC Lathe

Swing

1100 MM

Distance Between Centres

3000 MM

Spindle Bore

381 MM

Check Availability

View machine

Hankook Protec 11NE 2000 Flat Bed CNC Lathe

Swing

1100 MM

Distance Between Centres

2000 MM

Spindle Bore

381 MM

Check Availability

View machine

Hankook Protec 11ND 8000 Flat Bed CNC Lathe

Swing

1100 MM

Distance Between Centres

8000 MM

Spindle Bore

330 MM

Check Availability

View machine

Hankook Protec 11ND 7000 Flat Bed CNC Lathe

Swing

1100 MM

Distance Between Centres

7000 MM

Spindle Bore

330 MM

Check Availability

View machine

Hankook Protec 11ND 6000 Flat Bed CNC Lathe

Swing

1100 MM

Distance Between Centres

6000 MM

Spindle Bore

330 MM

Check Availability

View machine

Hankook Protec 11ND 5000 Flat Bed CNC Lathe

Swing

1100 MM

Distance Between Centres

5000 MM

Spindle Bore

330 MM

Check Availability

View machine

Hankook Protec 11ND 4000 Flat Bed CNC Lathe

Swing

1100 MM

Distance Between Centres

4000 MM

Spindle Bore

330 MM

Check Availability

View machine

Hankook Protec 11ND 3000 Flat Bed CNC Lathe

Swing

1100 MM

Distance Between Centres

3000 MM

Spindle Bore

330 MM

Check Availability

View machine

Hankook Protec 11ND 2000 Flat Bed CNC Lathe

Swing

1100 MM

Distance Between Centres

2000 MM

Spindle Bore

330 MM

Check Availability

View machine

Hankook Protec 11NA 8000 Flat Bed CNC Lathe

Swing

1100 MM

Distance Between Centres

8000 MM

Spindle Bore

105 MM

Check Availability

View machine

Hankook Protec 11NA 7000 Flat Bed CNC Lathe

Swing

1100 MM

Distance Between Centres

7000 MM

Spindle Bore

105 MM

Check Availability

View machine

Hankook Protec 11NA 6000 Flat Bed CNC Lathe

Swing

1100 MM

Distance Between Centres

6000 MM

Spindle Bore

105 MM

Check Availability

View machine

Hankook Protec 11NA 5000 Flat Bed CNC Lathe

Swing

1100 MM

Distance Between Centres

5000 MM

Spindle Bore

105 MM

Check Availability

View machine

Hankook Protec 11NA 4000 Flat Bed CNC Lathe

Swing

1100 MM

Distance Between Centres

4000 MM

Spindle Bore

105 MM

Check Availability

View machine

Hankook Protec 11NA 3000 Flat Bed CNC Lathe

Swing

1100 MM

Distance Between Centres

3000 MM

Spindle Bore

105 MM

Check Availability

View machine

Hankook Protec 11NA 2000 Flat Bed CNC Lathe

Swing

1100 MM

Distance Between Centres

2000 MM

Spindle Bore

105 MM

Check Availability

View machine

Hankook Protec 9NC 8000 Flat Bed CNC Lathe

Swing

950 MM

Distance Between Centres

8000 MM

Spindle Bore

254 MM

Check Availability

View machine

Hankook Protec 9NC 7000 Flat Bed CNC Lathe

Swing

950 MM

Distance Between Centres

7000 MM

Spindle Bore

254 MM

Check Availability

View machine

Hankook Protec 9NC 6000 Flat Bed CNC Lathe

Swing

950 MM

Distance Between Centres

6000 MM

Spindle Bore

254 MM

Check Availability

View machine

Hankook Protec 9NC 5000 Flat Bed CNC Lathe

Swing

950 MM

Distance Between Centres

5000 MM

Spindle Bore

254 MM

Check Availability

View machine

Hankook Protec 9NC 4000 Flat Bed CNC Lathe

Swing

950 MM

Distance Between Centres

4000 MM

Spindle Bore

254 MM

Check Availability

View machine

Hankook Protec 9NC 3000 Flat Bed CNC Lathe

Swing

950 MM

Distance Between Centres

3000 MM

Spindle Bore

254 MM

Check Availability

View machine

Hankook Protec 9NC 2000 Flat Bed CNC Lathe

Swing

950 MM

Distance Between Centres

2000 MM

Spindle Bore

254 MM

Check Availability

View machine

Hankook Protec 9NB 8000 Flat Bed CNC Lathe

Swing

950 MM

Distance Between Centres

8000 MM

Spindle Bore

176 MM

Check Availability

View machine

Hankook Protec 9NB 7000 Flat Bed CNC Lathe

Swing

950 MM

Distance Between Centres

7000 MM

Spindle Bore

176 MM

Check Availability

View machine

Hankook Protec 9NB 6000 Flat Bed CNC Lathe

Swing

950 MM

Distance Between Centres

6000 MM

Spindle Bore

176 MM

Check Availability

View machine

Hankook Protec 9NB 5000 Flat Bed CNC Lathe

Swing

950 MM

Distance Between Centres

5000 MM

Spindle Bore

176 MM

Check Availability

View machine

Hankook Protec 9NB 4000 Flat Bed CNC Lathe

Swing

950 MM

Distance Between Centres

4000 MM

Spindle Bore

176 MM

Check Availability

View machine

Hankook Protec 9NB 3000 Flat Bed CNC Lathe

Swing

950 MM

Distance Between Centres

3000 MM

Spindle Bore

176 MM

Check Availability

View machine

Hankook Protec 9NB 2000 Flat Bed CNC Lathe

Swing

950 MM

Distance Between Centres

2000 MM

Spindle Bore

176 MM

Check Availability

View machine

Hankook Protec 9NA 8000 Flat Bed CNC Lathe

Swing

950 MM

Distance Between Centres

8000 MM

Spindle Bore

105 MM

Check Availability

View machine

Hankook Protec 9NA 7000 Flat Bed CNC Lathe

Swing

950 MM

Distance Between Centres

7000 MM

Spindle Bore

105 MM

Check Availability

View machine

Hankook Protec 9NA 6000 Flat Bed CNC Lathe

Swing

950 MM

Distance Between Centres

6000 MM

Spindle Bore

105 MM

Check Availability

View machine

Hankook Protec 9NA 5000 Flat Bed CNC Lathe

Swing

950 MM

Distance Between Centres

5000 MM

Spindle Bore

105 MM

Check Availability

View machine

Hankook Protec 9NA 4000 Flat Bed CNC Lathe

Swing

950 MM

Distance Between Centres

4000 MM

Spindle Bore

105 MM

Check Availability

View machine

Hankook Protec 9NA 3000 Flat Bed CNC Lathe

Swing

950 MM

Distance Between Centres

3000 MM

Spindle Bore

105 MM

Check Availability

View machine

Hankook Protec 9NA 2000 Flat Bed CNC Lathe

Swing

950 MM

Distance Between Centres

2000 MM

Spindle Bore

105 MM

Check Availability

View machine

USED HAAS SL-40 Slant Bed 2-Axis CNC Lathe – TWW Cat 7965

USED 2008

Swing

1016 MM

Distance Between Centres

1295 MM

Spindle Bore

100 MM

Ex Stock - Subject to Prior Sale

View machine

HD2200, HD2200C Slant Bed 2-Axis CNC Lathe

IN STOCK

Swing

630 MM

Distance Between Centres

659 MM

Spindle Bore

81 MM

Ex Stock - Subject to Prior Sale

View machine

Gurutzpe GL10 Series Flat Bed CNC Lathe

Swing

1000 MM

Distance Between Centres

3000 MM

Spindle Bore

130 MM

Check Availability

View machine

Takisawa Japan TT2600CMG Series Gantry Loaded Twin Spindle CNC Lathe, C-Axis & Live Tools

Swing

420 MM

Distance Between Centres

185 MM

Spindle Bore

0 MM

Check Availability

View machine

Takisawa Japan TT2600G Series Gantry Loaded Twin Spindle CNC Lathe

Swing

420 MM

Distance Between Centres

185 MM

Spindle Bore

0 MM

Check Availability

View machine

Takisawa Japan T2600G Series Gantry Loaded Single Spindle CNC Lathe

Swing

420 MM

Distance Between Centres

185 MM

Spindle Bore

0 MM

Check Availability

View machine

Takisawa Japan TT2100CMG Gantry Loaded Twin Spindle CNC Lathe, C-Axis & Live Tools

Swing

140 MM

Distance Between Centres

135 MM

Spindle Bore

53 MM

Check Availability

View machine

Takisawa Japan TT2100G Gantry Loaded Twin Spindle CNC Lathe

Swing

140 MM

Distance Between Centres

121 MM

Spindle Bore

53 MM

Check Availability

View machine

Takisawa Japan TT1100CMG Gantry Loaded Twin Spindle CNC Lathe, C-Axis & Live Tools

Swing

140 MM

Distance Between Centres

121 MM

Spindle Bore

53 MM

Check Availability

View machine

Takisawa Japan TT1100G Gantry Loaded Twin Spindle CNC Lathe

Swing

140 MM

Distance Between Centres

121 MM

Spindle Bore

53 MM

Check Availability

View machine

Takisawa Japan TCC2000G Series Gantry Loaded Single Spindle CNC Lathe

Swing

420 MM

Distance Between Centres

185 MM

Spindle Bore

0 MM

Check Availability

View machine

Hyundai-Wia LM2500TTSY II Slant Bed, Y-Axis CNC Lathe with Twin Spindle & Twin Turrets

NEW MODEL

Swing

780 MM

Distance Between Centres

900 MM

Spindle Bore

81 MM

Check Availability

View machine

Hyundai-Wia LM1800TTSY Slant Bed, Y-Axis CNC Lathe with Twin Spindle & Twin Turrets

Swing

290 MM

Distance Between Centres

673 MM

Spindle Bore

65 MM

Check Availability

View machine

Hyundai-Wia L5100LY Slant Bed, Y-Axis CNC Lathe

NEW MODEL

Swing

1030 MM

Distance Between Centres

2070 MM

Spindle Bore

165 MM

Check Availability

View machine

Hyundai-Wia L3000Y L3000LY Slant Bed, Y-Axis CNC Lathe

NEW MODEL

Swing

800 MM

Distance Between Centres

760 MM

Spindle Bore

102 MM

Check Availability

View machine

Hyundai-Wia L2600SY Slant Bed, Y-Axis CNC Lathe with Sub Spindle

Swing

800 MM

Distance Between Centres

760 MM

Spindle Bore

81 MM

Check Availability

View machine

Hyundai-Wia L2600Y L2600LY Slant Bed, Y-Axis CNC Lathe

NEW MODEL

Swing

800 MM

Distance Between Centres

760 MM

Spindle Bore

81 MM

Check Availability

View machine

Hyundai-Wia L2000Y L2000LY Slant Bed, Y-Axis CNC Lathe

NEW MODEL

Swing

800 MM

Distance Between Centres

520 MM

Spindle Bore

65 MM

Check Availability

View machine

Hyundai-Wia L5100LMC Slant Bed CNC Lathe, C Axis & Driven Tools

NEW MODEL

Swing

1030 MM

Distance Between Centres

2120 MM

Spindle Bore

165 MM

Check Availability

View machine

Hyundai-Wia L5100LM Slant Bed CNC Lathe, C Axis & Driven Tools

NEW MODEL

Swing

1030 MM

Distance Between Centres

2120 MM

Spindle Bore

165 MM

Check Availability

View machine

Hyundai-Wia L5100LC Slant Bed 2-Axis CNC Lathe

NEW MODEL

Swing

1030 MM

Distance Between Centres

2205 MM

Spindle Bore

275 MM

Check Availability

View machine

Hyundai-Wia L5100L Slant Bed 2-Axis CNC Lathe

NEW MODEL

Swing

1030 MM

Distance Between Centres

2205 MM

Spindle Bore

165 MM

Check Availability

View machine

Hyundai-Wia L4000MC L4000LMC Slant Bed CNC Lathe, C Axis & Driven Tools

NEW MODEL

Swing

800 MM

Distance Between Centres

940 MM

Spindle Bore

165 MM

Check Availability

View machine

Hyundai-Wia L4000C L4000LC Slant Bed 2-Axis CNC Lathe

NEW MODEL

Swing

800 MM

Distance Between Centres

1043 MM

Spindle Bore

117 MM

Check Availability

View machine

Hyundai-Wia L4000M L4000LM Slant Bed CNC Lathe, C Axis & Driven Tools

IN STOCK

Swing

800 MM

Distance Between Centres

958 MM

Spindle Bore

117 MM

Ex Stock - Subject to Prior Sale

View machine

Hyundai-Wia L4000 L4000L Slant Bed 2-Axis CNC Lathe

NEW MODEL

Swing

800 MM

Distance Between Centres

1043 MM

Spindle Bore

117 MM

Check Availability

View machine

Hyundai-Wia SE2600SY Slant Bed, Y-Axis CNC Lathe with Sub Spindle

NEW MODEL

Swing

630 MM

Distance Between Centres

630 MM

Spindle Bore

81 MM

Check Availability

View machine

Hyundai-Wia SE2600Y Slant Bed, Y-Axis CNC Lathe

NEW MODEL

Swing

630 MM

Distance Between Centres

630 MM

Spindle Bore

81 MM

Check Availability

View machine

Hyundai-Wia SE2600M Slant Bed CNC Lathe, C Axis & Driven Tools

NEW MODEL

Swing

600 MM

Distance Between Centres

630 MM

Spindle Bore

81 MM

Check Availability

View machine

Hyundai-Wia SE2600 Slant Bed 2-Axis CNC Lathe

Swing

600 MM

Distance Between Centres

671 MM

Spindle Bore

81 MM

Check Availability

View machine

Takisawa Japan TM-3000Y2 Slant Bed, Y-Axis CNC Lathe with Twin Spindle & Twin Turrets

IN STOCK

Swing

215 MM

Distance Between Centres

620 MM

Spindle Bore

65 MM

Ex Stock - Subject to Prior Sale

View machine

Takisawa Japan TM-4000Y2 Slant Bed, Y-Axis CNC Lathe with Twin Spindle & Twin Turrets

IN STOCK

Swing

215 MM

Distance Between Centres

800 MM

Spindle Bore

65 MM

Ex Stock - Subject to Prior Sale

View machine

USED TAKISAWA JAPAN TPS3300 Slant Bed CNC Lathe, Elliptical Gudgeon Pin Hole Machining – TWW Cat 7853

USED 2005

Swing

0 MM

Distance Between Centres

0 MM

Spindle Bore

0 MM

Ex Stock - Subject to Prior Sale

View machine

USED PINACHO ST-310-105 X 2000 3-Axis Flat Bed CNC Lathe with C-Axis & Driven Tools – TWW Cat 7874

USED 2017

Swing

620 MM

Distance Between Centres

2000 MM

Spindle Bore

105 MM

Ex Stock - Subject to Prior Sale

View machine

Takisawa Taiwan LX-2500 Series Slant Bed 2-Axis CNC Lathe

NEW MODEL

Swing

625 MM

Distance Between Centres

732 MM

Spindle Bore

81 MM

Check Availability

View machine

Takisawa Taiwan LX-2500M Series Slant Bed CNC Lathe, C Axis & Driven Tools

NEW MODEL

Swing

730 MM

Distance Between Centres

698 MM

Spindle Bore

81 MM

Check Availability

View machine

Takisawa Taiwan LX-2500Y Series Slant Bed, Y-Axis CNC Lathe

NEW MODEL

Swing

730 MM

Distance Between Centres

698 MM

Spindle Bore

81 MM

Check Availability

View machine

Takisawa Taiwan NEX-110 Series Slant Bed 2-Axis CNC Lathe

Swing

495 MM

Distance Between Centres

657 MM

Spindle Bore

75 MM

Check Availability

View machine

Takisawa Taiwan NEX-108 Series Slant Bed 2-Axis CNC Lathe

IN STOCK

Swing

400 MM

Distance Between Centres

481 MM

Spindle Bore

52 MM

Ex Stock - Subject to Prior Sale

View machine

Takisawa Taiwan NEX-106 Series Slant Bed 2-Axis CNC Lathe

Swing

350 MM

Distance Between Centres

350 MM

Spindle Bore

43 MM

Check Availability

View machine

Takisawa Taiwan LA-350 Series Slant Bed 2-Axis CNC Lathe

Swing

780 MM

Distance Between Centres

830 MM

Spindle Bore

115 MM

Check Availability

View machine

Takisawa Taiwan LA-450M Series Slant Bed CNC Lathe, C Axis & Driven Tools

Swing

780 MM

Distance Between Centres

662 MM

Spindle Bore

150 MM

Check Availability

View machine

Takisawa Taiwan LA-350M Series Slant Bed CNC Lathe, C Axis & Driven Tools

Swing

780 MM

Distance Between Centres

711 MM

Spindle Bore

115 MM

Check Availability

View machine

Takisawa Taiwan LA-350M Slant Bed CNC Lathe, C Axis & Driven Tools

Swing

480 MM

Distance Between Centres

711 MM

Spindle Bore

115 MM

Check Availability

View machine

Takisawa Taiwan LA-450 Series Slant Bed 2-Axis CNC Lathe

Swing

780 MM

Distance Between Centres

781 MM

Spindle Bore

150 MM

Check Availability

View machine

Takisawa Taiwan NX-2500MT Series 3-Axis Slant Bed CNC Turning Centre with C-Axis & Driven Tools

NEW MODEL

Swing

400 MM

Distance Between Centres

736 MM

Spindle Bore

75 MM

Check Availability

View machine

Takisawa Taiwan NX-2500MS Slant Bed CNC Lathe, C Axis, Driven Tools & Sub Spindle

NEW MODEL

Swing

400 MM

Distance Between Centres

736 MM

Spindle Bore

75 MM

Check Availability

View machine

Takisawa Taiwan NX-2500YT Series Slant Bed, Y-Axis CNC Lathe

NEW MODEL

Swing

400 MM

Distance Between Centres

736 MM

Spindle Bore

75 MM

Check Availability

View machine

Takisawa Taiwan NX-2500YS Series Slant Bed, Y-Axis CNC Lathe with Sub Spindle

NEW MODEL

Swing

400 MM

Distance Between Centres

736 MM

Spindle Bore

75 MM

Check Availability

View machine

Hyundai-Wia HD3100M HD3100LM Slant Bed CNC Lathe, C Axis & Driven Tools

IN STOCK

Swing

750 MM

Distance Between Centres

740 MM

Spindle Bore

102 MM

Ex Stock - Subject to Prior Sale

View machine

Hyundai-Wia HD3100YA Slant Bed, Y-Axis CNC Lathe

IN STOCK

Swing

420 MM

Distance Between Centres

760 MM

Spindle Bore

81 MM

Ex Stock - Subject to Prior Sale

View machine

Hyundai-Wia HD3100 HD3100L Slant Bed 2-Axis CNC Lathe

IN STOCK

Swing

750 MM

Distance Between Centres

780 MM

Spindle Bore

102 MM

Ex Stock - Subject to Prior Sale

View machine

Hyundai-Wia HD3100SY Y-Axis CNC Lathe with Sub Spindle

Swing

420 MM

Distance Between Centres

760 MM

Spindle Bore

102 MM

Check Availability

View machine

Hyundai-Wia LM1600TTSY Slant Bed, Y-Axis CNC Lathe with Twin Spindle & Twin Turrets

Swing

290 MM

Distance Between Centres

705 MM

Spindle Bore

51 MM

Check Availability

View machine

Hyundai-Wia L3000SY Slant Bed, Y-Axis CNC Lathe with Sub Spindle

NEW MODEL

Swing

800 MM

Distance Between Centres

760 MM

Spindle Bore

102 MM

Check Availability

View machine

Hyundai-Wia HD3100Y Slant Bed, Y-Axis CNC Lathe

Swing

420 MM

Distance Between Centres

760 MM

Spindle Bore

102 MM

Check Availability

View machine

Hyundai-Wia HD2600SY Slant Bed, Y-Axis CNC Lathe with Sub Spindle

Swing

300 MM

Distance Between Centres

610 MM

Spindle Bore

81 MM

Check Availability

View machine

Hyundai-Wia HD2600Y Slant Bed, Y-Axis CNC Lathe

IN STOCK

Swing

820 MM

Distance Between Centres

610 MM

Spindle Bore

81 MM

Check Availability

View machine

Hyundai-Wia HD2200SY Slant Bed, Y-Axis CNC Lathe with Sub Spindle

Swing

820 MM

Distance Between Centres

610 MM

Spindle Bore

65 MM

Check Availability

View machine

Hyundai-Wia SE2200LSY Slant Bed, Y-Axis CNC Lathe with Sub Spindle

IN STOCK

Swing

300 MM

Distance Between Centres

510 MM

Spindle Bore

65 MM

Ex Stock - Subject to Prior Sale

View machine

Hyundai-Wia SE2200LSYA Slant Bed, Y-Axis CNC Lathe with Sub Spindle

Swing

300 MM

Distance Between Centres

529 MM

Spindle Bore

51 MM

Check Availability

View machine

Hyundai-Wia SE2200LYA Slant Bed, Y-Axis CNC Lathe

Swing

300 MM

Distance Between Centres

529 MM

Spindle Bore

51 MM

Check Availability

View machine

Hyundai-Wia SE2200Y Slant Bed, Y-Axis CNC Lathe

SHORT DEL

Swing

300 MM

Distance Between Centres

288 MM

Spindle Bore

65 MM

Check Availability

View machine

Hyundai-Wia SE2200YA Slant Bed, Y-Axis CNC Lathe

Swing

300 MM

Distance Between Centres

309 MM

Spindle Bore

51 MM

Check Availability

View machine

Hyundai-Wia SE2200LMSC Slant Bed CNC Lathe, C Axis, Driven Tools & Sub Spindle

Swing

300 MM

Distance Between Centres

499 MM

Spindle Bore

81 MM

Check Availability

View machine

Hyundai-Wia SE2200LMC Slant Bed CNC Lathe, C Axis & Driven Tools

Swing

300 MM

Distance Between Centres

499 MM

Spindle Bore

81 MM

Check Availability

View machine

Hyundai-Wia SE2200LC Slant Bed 2-Axis CNC Lathe

Swing

350 MM

Distance Between Centres

549 MM

Spindle Bore

81 MM

Check Availability

View machine

Hyundai-Wia SE2200LMS Slant Bed CNC Lathe, C Axis, Driven Tools & Sub Spindle

Swing

300 MM

Distance Between Centres

508 MM

Spindle Bore

65 MM

Short Delivery - Subject to Prior Sale

View machine

Hyundai-Wia SE2200LM Slant Bed CNC Lathe, C Axis & Driven Tools

Swing

300 MM

Distance Between Centres

508 MM

Spindle Bore

65 MM

Check Availability

View machine

Hyundai-Wia SE2200M Slant Bed CNC Lathe, C Axis & Driven Tools

IN STOCK

Swing

300 MM

Distance Between Centres

288 MM

Spindle Bore

65 MM

Ex Stock - Subject to Prior Sale

View machine

Hyundai-Wia SE2200L Slant Bed 2-Axis CNC Lathe

Swing

350 MM

Distance Between Centres

558 MM

Spindle Bore

65 MM

Check Availability

View machine

Hyundai-Wia SE2200 Slant Bed 2-Axis CNC Lathe

Swing

350 MM

Distance Between Centres

307 MM

Spindle Bore

65 MM

Check Availability

View machine

Hyundai-Wia SE2200LMSA Slant Bed CNC Lathe, C Axis, Driven Tools & Sub Spindle

Swing

300 MM

Distance Between Centres

529 MM

Spindle Bore

51 MM

Check Availability

View machine

Hyundai-Wia SE2200LMA Slant Bed CNC Lathe, C Axis & Driven Tools

Swing

300 MM

Distance Between Centres

529 MM

Spindle Bore

51 MM

Check Availability

View machine

Hyundai-Wia SE2200MA Slant Bed CNC Lathe, C Axis & Driven Tools

Swing

300 MM

Distance Between Centres

309 MM

Spindle Bore

51 MM

Check Availability

View machine

Hyundai-Wia SE2200LA Slant Bed 2-Axis CNC Lathe

Swing

350 MM

Distance Between Centres

560 MM

Spindle Bore

51 MM

Check Availability

View machine

Hyundai-Wia SE2200A Slant Bed 2-Axis CNC Lathe

Swing

350 MM

Distance Between Centres

340 MM

Spindle Bore

51 MM

Check Availability

View machine

Hyundai-Wia SE2200LY Slant Bed, Y-Axis CNC Lathe

IN STOCK

Swing

300 MM

Distance Between Centres

508 MM

Spindle Bore

65 MM

Ex Stock - Subject to Prior Sale

View machine

Hyundai-Wia HD3100SYA Slant Bed, Y-Axis CNC Lathe with Sub Spindle

Swing

420 MM

Distance Between Centres

760 MM

Spindle Bore

81 MM

Check Availability

View machine

Hyundai-Wia HD2600 Slant Bed 2-Axis CNC Lathe

IN STOCK

Swing

630 MM

Distance Between Centres

659 MM

Spindle Bore

81 MM

Check Availability

View machine

Hyundai-Wia HD2600M Slant Bed CNC Lathe, C Axis & Driven Tools

Swing

630 MM

Distance Between Centres

613 MM

Spindle Bore

81 MM

Ex Stock Subject to Prior Sale

View machine

Hyundai-Wia HD2200M HD2200MC Slant Bed CNC Lathe, C Axis & Driven Tools

Swing

550 MM

Distance Between Centres

467 MM

Spindle Bore

65 MM

Check Availability

View machine

Takisawa Taiwan FX-800 Series. Slant Bed, Y-Axis CNC Lathe with Twin Spindle & Twin Turrets

Swing

310 MM

Distance Between Centres

657 MM

Spindle Bore

65 MM

Check Availability

View machine

Hyundai-Wia HD2200Y Slant Bed, Y-Axis CNC Lathe

IN STOCK

Swing

820 MM

Distance Between Centres

610 MM

Spindle Bore

65 MM

Ex Stock - Subject to Prior Sale

View machine

Hyundai-Wia L600LA Slant Bed 2-Axis CNC Lathe

Swing

920 MM

Distance Between Centres

3250 MM

Spindle Bore

139 MM

Check Availability

View machine

Hyundai-Wia L800LMA Slant Bed CNC Lathe, C Axis & Driven Tools

Swing

920 MM

Distance Between Centres

3250 MM

Spindle Bore

319 MM

Check Availability

View machine

Hyundai-Wia L700LMA Slant Bed CNC Lathe, C Axis & Driven Tools

Swing

920 MM

Distance Between Centres

3250 MM

Spindle Bore

165 MM

Check Availability

View machine

Hyundai-Wia L600LMA Slant Bed CNC Lathe, C Axis & Driven Tools

Swing

920 MM

Distance Between Centres

3250 MM

Spindle Bore

139 MM

Check Availability

View machine

Hyundai-Wia L800LA Slant Bed 2-Axis CNC Lathe

Swing

920 MM

Distance Between Centres

3250 MM

Spindle Bore

319 MM

Check Availability

View machine

Hyundai-Wia L2000SY L2000LSY Slant Bed, Y-Axis CNC Lathe with Sub Spindle

Swing

800 MM

Distance Between Centres

520 MM

Spindle Bore

65 MM

Check Availability

View machine

Hyundai-Wia L300MSC Slant Bed CNC Lathe, C Axis, Driven Tools & Sub Spindle

Swing

500 MM

Distance Between Centres

600 MM

Spindle Bore

90 MM

Check Availability

View machine

Hyundai-Wia L300MSA L300LMSA Slant Bed CNC Lathe, C Axis, Driven Tools & Sub Spindle

Swing

410 MM

Distance Between Centres

680 MM

Spindle Bore

76 MM

Check Availability

View machine

Hyundai-Wia L300MA L300LMA Slant Bed CNC Lathe, C Axis & Driven Tools

IN STOCK

Swing

410 MM

Distance Between Centres

680 MM

Spindle Bore

76 MM

Ex Stock - Subject to Prior Sale

View machine

Hyundai-Wia L300MC L300LMC Slant Bed CNC Lathe, C Axis & Driven Tools

Swing

500 MM

Distance Between Centres

600 MM

Spindle Bore

90 MM

Check Availability

View machine

Takisawa Japan TCC1100G TCC2100G Series Gantry Loaded Single Spindle CNC Lathe

Swing

200 MM

Distance Between Centres

171 MM

Spindle Bore

53 MM

Check Availability

View machine

Hyundai-Wia L300C, L300LC Slant Bed 2-Axis CNC Lathe

Swing

560 MM

Distance Between Centres

720 MM

Spindle Bore

90 MM

Check Availability

View machine

Hyundai-Wia L300A L300LA Slant Bed 2-Axis CNC Lathe

Swing

500 MM

Distance Between Centres

720 MM

Spindle Bore

76 MM

Check Availability

View machine