News

News

Published: 25th August 2021 Author: anthony cogswell

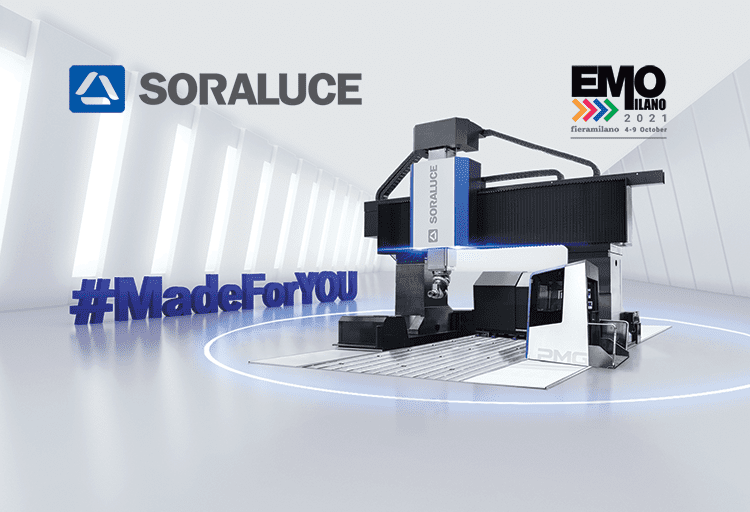

Soraluce will present its #MadeForYOU client-oriented approach, showcasing its leading generation of machining solutions, along with the most competitive technologies and services, during EMO 2021 in Milan.

The European manufacturer will take its latest developments in milling, boring and vertical turning machines, multitasking solutions, along with automation lines and “best in class” services, to the event. It is one of the most comprehensive and advanced machinery range on the market, which is also designed to be customised to each client’s specific requirements.

One its highlights at the event will be the SORALUCE PMG portal gantry milling machine, to be presented to the Italian market for the first time. The model has a longitudinal traverse of 10,000 mm, a cross traverse of 4,000 mm and a vertical traverse of 1,500 mm, fitted with a stepless universal head of 0.001º x 0.001º at 7,000 rpm.

As a trail-blazer in the use of linear guiding systems, it has applied all its expertise to the development of these new portal machines. They combine the linear guiding technology with the damping systems by means of incorporating solutions such as DAS®, an active damping system to eliminate chatter and exclusive to Soraluce.

The result is highly productive machines, with great precision, that are dynamic, stable during machining and reliable as regards to availability.

In keeping with the #MadeForYOU philosophy, the new portal model can be customised to meet each client’s requirements, where the work areas can be configured to optimise productivity, by minimising shutdowns while fitting the workpiece, or to increase the versatility and flexibility of the machine, by incorporating the multitask feature with rotary tables for milling and turning. Its options include milling and turning heads and tool storage.

The machine-tool manufacturer assembles this type of machine at its state-of-the-art Soraluce Portal Factory. The company has invested €9 million in the facilities to create a modern and advanced manufacturing centre, that is one-of-a-kind in its category in the world and dedicated to the manufacturing of portal machines.

Along with the latest developments in the portal machinery range, Soraluce professionals will show visitors to the fair the company’s whole range of milling machines, multitasking solutions and automation lines. The visitors will also have the chance to learn about the portfolio of “best in class” services that increase the precision, productivity and profitability levels of machining.

Soraluce continues to consolidate its great commitment to technology, by developing high value-added services and offering expert advice to its clients. Thus, during the fair, Soraluce will showcase smart damping solutions to increase stock removal during the machining. The solutions have been developed thanks to the company’s high technical expertise and its knowledge of engineering applied to manufacturing solutions. The visitors will also have the chance to find out about these technologies for themselves during the live demonstrations.

The manufacturer has developed different systems to eliminate chatter, thus increasing the cutting capacity of the equipment and the efficiency of the machining processes.

On the one hand, Soraluce will showcase its renowned active damping system, DAS, the smart system that oversees the machining process and selects the best technological alternative to eliminate chatter. Fitted with a very simple interface, this solution allows the evolution of the process to be controlled, by providing comprehensive information on the chatter, the vibration level and the technologies used to suppress it; such as the active damping of the ram, the tuning of the optimum spindle speed of the tool and the harmonic oscillation of the spindle speed.

On the other hand, there will also be a live presentation of the DWS (Dynamic Workpiece Stabilizer) system, an active damping device that eliminates the chatter that is usually generated when machining flexible parts. This patented system, which was the winner of the Prize award in the International Quality Innovation of the Year 2020 competition, provides an effective solution for the problems associated with machining slim-format parts and is an improvement on traditional alternatives.

Soraluce, since their foundation almost 60 years ago have been exclusively represented in the United Kingdom and Irish Republic by T.W. Ward CNC Machinery Ltd (Ward CNC). Commenting on the range of Portal machines, Ward CNC’s Head of Strategic Accounts & Projects, Stuart Lawson, says: “Soraluce continue to provide innovative and industry leading solutions. Their unrivalled production technologies for single set-up: milling, boring, turning and grinding is of particular significance as Ward CNC are currently seeing an increase of new opportunities for this type of machine.

This level of innovation from Soraluce partnered with Ward CNC’s service back up and engineering expertise gives confidence to customers in the UK that we can continue to provide solutions to their production problems, no matter the material or size of workpiece.”

Last Updated: March 11, 2024