News

News

Published: 15th April 2019 Author: anthony cogswell

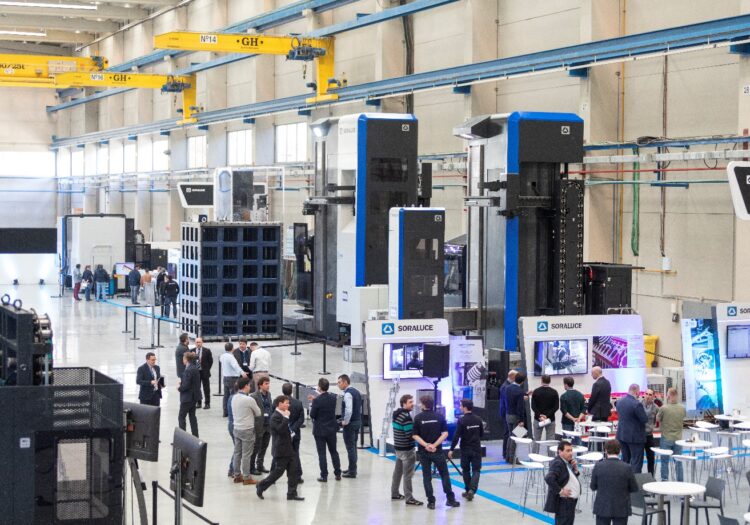

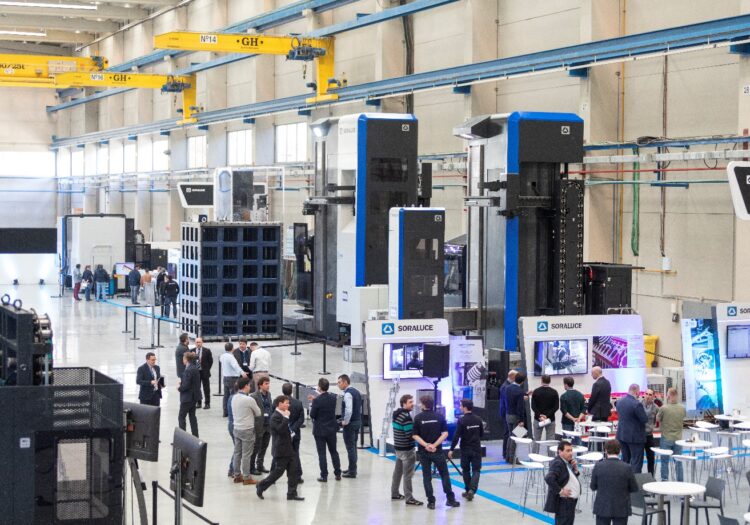

Soraluce’s opening of a new factory dedicated to the assembly of portal-type machining centres, coupled with the launch of a new range of “redesigned and revitalised” machines, has not only reinforced the company’s world lead in portal-type machining technology but the accompanying innovative technology developments for continually-improved machining routines.

The improved machining routines includes single set-up milling, boring, turning and grinding and also highlights the company’s constant progress and expertise in providing customers with complete manufacturing solutions.

The three-day Portal Summit event also enabled the company to showcase a new compact range (TA Series) of bed-type milling machines where grinding has now been added to the capabilities of milling, boring and turning in the same set-up.

In addition to the new machines, Soraluce also demonstrated a range of technology innovations, including the new:

These complement the company’s existing innovative manufacturing tools of:

Commenting on the event and the new range, Ward CNC’s Head of Strategic Accounts & Projects, Stuart Lawson, says: “Soraluce’s ongoing commitment to machining excellence, combined with industry leading innovative solutions provides Ward CNC customers with immediate access to unrivalled production technologies in terms of milling, boring, turning – and now also grinding – in a single set-up. This partnered with our own ultra-high levels of engineering applications expertise and service back-up, means UK customers can continue to rely on Ward CNC to provide cost-effective answers to their production problems, for workpieces of every size and in all materials.”

Last Updated: March 11, 2024